Mining Application

Mining Pumps In Gold Mine

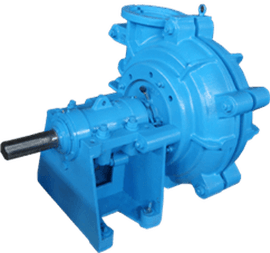

Slurry pumps work as mining pumps used in many mining industries, including gold and copper. An example of an application in the gold industry is the gravity beneficiation system, which uses the difference in specific gravity between gold and other minerals to separate them. The gold-bearing ore is placed in a cylindrical sieve and rinsed with high-pressure water. The gravel that is larger than the sieve hole is transported to the tailings by slip and belt; The jig, after three stages of jig concentrate flows into the shaker, performs coarse, fine, and sweeping actions to produce fine gold.

In recent years, the reselection process for the extraction of gold from rock gold mines has developed rapidly. There have been many new or expanded large-scale rock gold mines abroad that use the reselection method to extract single gold in the grinding circuit. Slurry pumps continue to be the most important tools in extracting gold from sand ore, because of their simple re-selection process, low cost, and effectiveness in capturing single-grained gold.

Mining pumps are used to transport the slurry resulting from the single flotation method for processing natural coarse and medium grain gold iron ore. The crushed ore enters the ball mill and is ground into a slurry before flotation. During flotation, sodium carbonate is used as a regulator to float the gold.

Mining pumps are also used to transport the slurry involved in mercury-mixed flotation for processing coarse gold inlays, which are stored in pyrite and other sulfide ores. Differing from single flotation, a mercury plate is added to recover gold after grinding, resulting in recovery rates between 30-45%. The mercury-mixed pulp is then floated through the classifier overflow. To optimize results, concentrated sodium carbonate and caustic soda are added during grinding and can increase mercury and gold recovery rates by up to 70%.